2 min read

Introducing PMC-Colinet’s New 4-Axis Threading Solution

PMC-Colinet, a trusted name in pipe threading machine manufacturing, has launched an advanced 4-axis threading module designed to meet ...

PMC-Colinet designs and builds high-performance, custom pipe threading and coupling machines for OCTG and industrial manufacturing, delivering efficiency, durability, and expert-backed reliability.

PMC-Colinet™ railway machines are expertly designed to ensure wheelsets are precisely reprofiled for optimal performance, protecting your railway infrastructure from unnecessary wear and damage while increasing your wheelset lifetime.

Built to last longer than competitor machines, our railway solutions deliver unmatched accuracy and reliability, seamlessly integrating into your existing operations. These versatile machines can handle wheelsets with or without brake discs, wheelsets with internal or external bearing boxes, and can even be configured in a tandem system to machine two wheelsets simultaneously — significantly increasing production speed. With a focus on durability, efficiency and adaptability, PMC-Colinet’s wheelsets lathes are the perfect choice for the reprofiling of wheelsets.

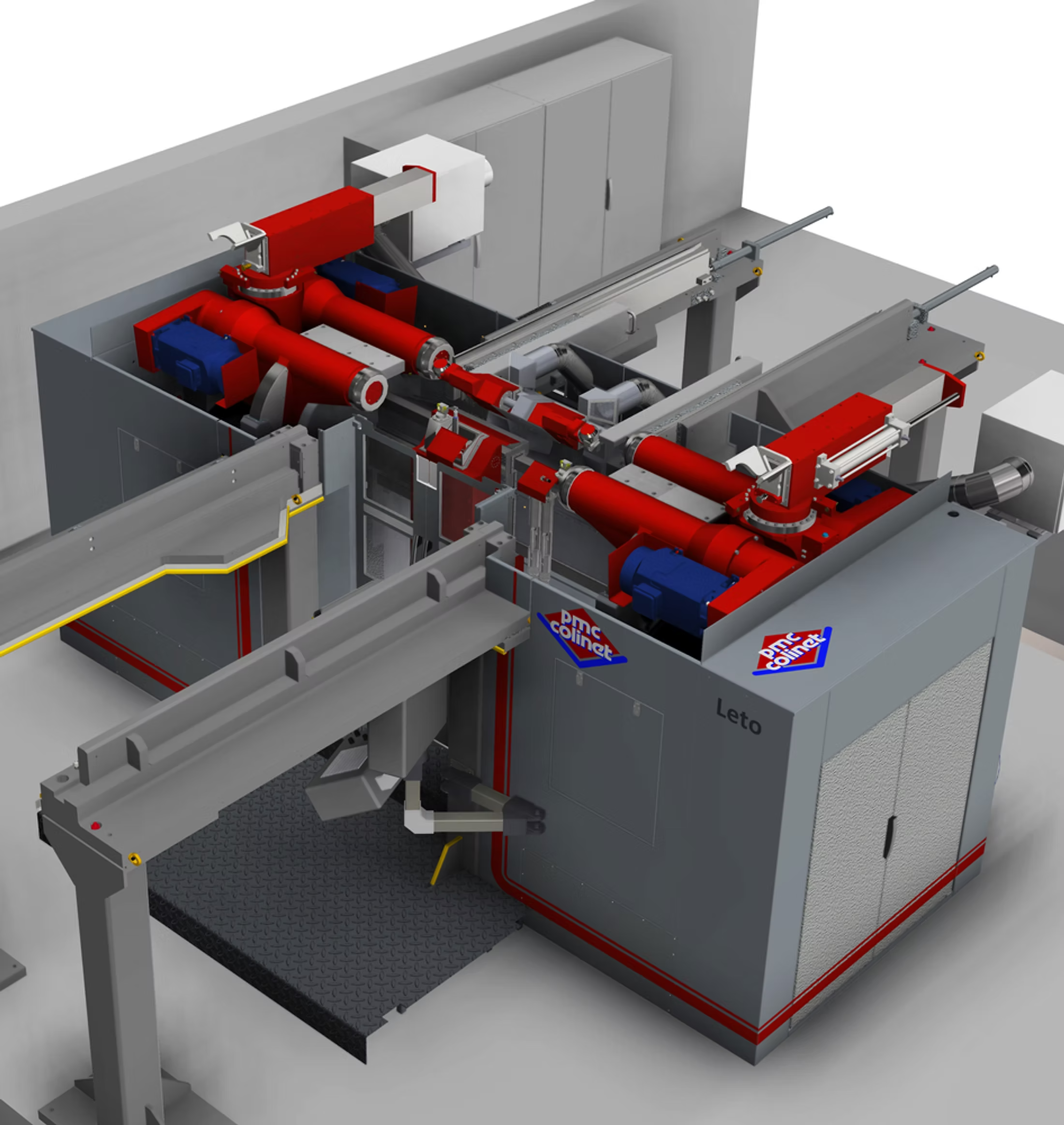

The LETO Series heavyweight underfloor wheelset lathe is designed to handle the most demanding wheelset reprofiling machining with precision and reliability. Capable of machining a wide variety of wheelsets — including those with external or internal bearing boxes, mechanically connected wheels and wheels with or without brake discs — the LETO Series offers unmatched versatility. The machine is designed to adapt the machining of wheelset diameters varying from 500 mm to 1,600 mm, thus allowing the reprofiling of steam locomotive wheelsets. For high-demand applications, the LETO Series can be configured as a tandem system, with two machines positioned side by side to reprofile two wheelsets simultaneously.

Used Standards: European Norms 2006/42/CE

Min Distance Between Consecutive Wheel Sets: 1100 mm

Wheel Outside Diameter: 500 mm to 1600 mm

Max Load per Wheel Set: 300 kN (30 t)

For steam locomotive application, machine can handle up to 400 kN (40 t)

Series of Wheel Sets That Can Be Machined:

With external bearing boxes

With internal bearing boxes

Mechanically connected

With or without brake disc

Can reprofile standalone bogies or standalone wheel sets as long as the external preloads are used and considering they are hoisted by the crane to reach the working position.

Series of Wheels That Can Be Machined

Monolithic wheels with conical or corrugated rim

Monolithic wheels

Wheels with flanged brake discs

Series of Brake Discs

Monolithic discs fixed on the shaft

Sectored discs fixed on the shaft

Monolithic discs flanged on the inside or on the outside of the wheel

Sectored discs flanged on the inside or on the outside of the wheel

Max Chip Size: 10 mm2

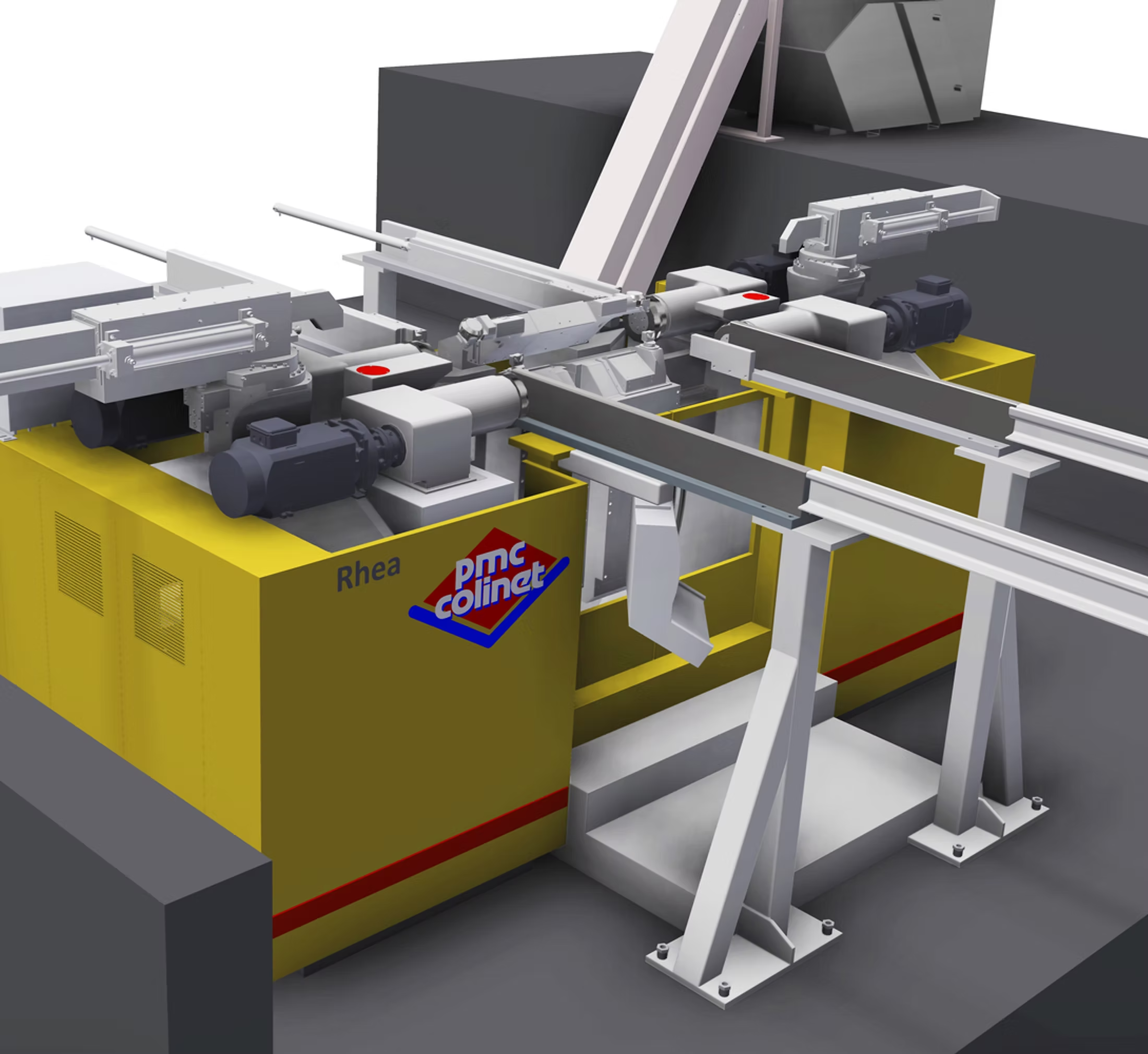

The RHEA Series underfloor wheel lathe is the ultimate solution for the precision reprofiling of wheelsets and brake discs. With the ability to handle wheelsets that have external bearing boxes — mechanically connected or with or without brake discs — the RHEA Series adapts to your needs seamlessly. Designed for heavy-duty operations, it boasts a maximum load capacity of 150 kN (15 t). Trust the RHEA Series to deliver unmatched versatility and performance for your subway operations.

Used Standards: European Norms 2006/42/CE

Wheel Outside Diameter: 750 mm to 900 mm

Max Load per Wheel Set: 150 kN (15 t)

Series of Wheel Sets That Can Be Machined:

With external bearing boxes

Mechanically connected

With or without brake disc

Capability to Re-Machine Brake Discs: Yes

The TETHYS Series underfloor wheel lathe is specifically engineered to meet the unique demands of tramway operations. With the same adaptable versatility as the RHEA Series, it effortlessly handles wheel sets with external bearing boxes, mechanically connected or with or without brake discs. Designed for lighter applications, it supports a maximum load of 100 kN (10 t). The TETHYS Series ensures precise reprofiling and reliable performance tailored to tramway requirements.

Used Standards: European Norms 2006/42/CE

Wheel Outside Diameter: 580 mm to 630 mm

Max Load per Wheel Set: 100 kN (10 t)

Series of Wheel Sets That Can Be Machined:

With external bearing boxes

Mechanically connected

With or without brake disc

Capability to Re-Machine Brake Discs: Yes

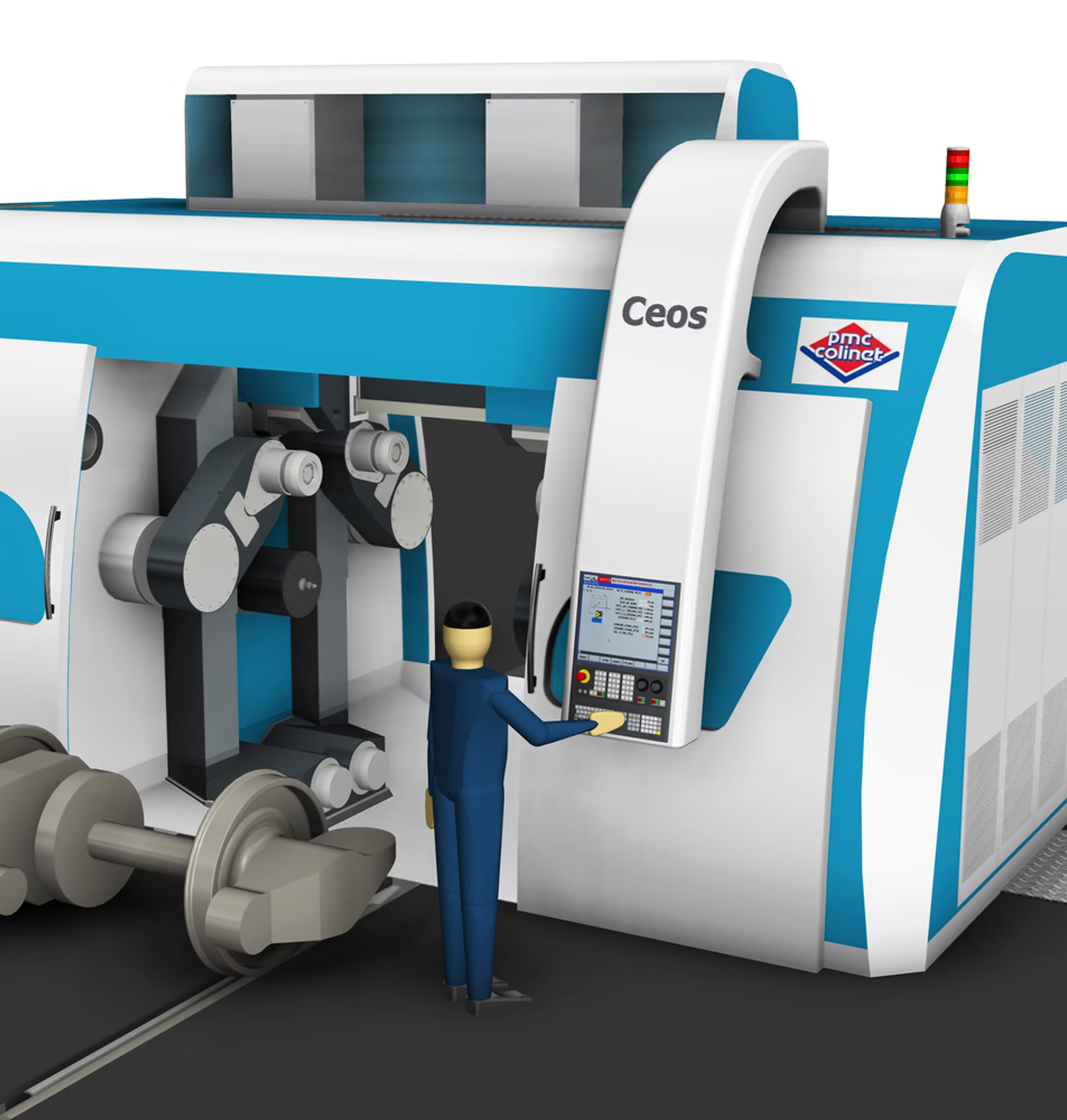

The CEOS Series upfloor wheel lathe is built for heavy-duty precision and unmatched versatility. Designed to reprofile wheelsets that have been removed from the railway cars, it handles a maximum load of 50 kN (5 t) per wheelset. The CEOS Series goes beyond standard reprofiling by offering the capability to machine a wide range of brake disc configurations. Whether you require monolithic discs fixed on the shaft, sectored discs or flanged discs — inside or outside the wheel — the CEOS Series delivers consistent, high-quality results. With its adaptable features and robust performance, the CEOS Series is the ideal solution for demanding rail operations.

Used Standards: European Norms 2006/42/CE

Wheel Outside Diameter: 540 mm to 1450 mm

Max Load per Wheel Set: 50 kN (5 t)

Series of Wheel Sets That Can Be Machined:

With external bearing boxes

With internal bearing boxes

With or without brake disc

Series of Wheels That Can Be Machined

Monolithic wheels with conical or corrugated rim

Monolithic wheels

Wheels with flanged brake discs

Series of Brake Discs

Monolithic discs fixed on the shaft

Sectored discs fixed on the shaft

Monolithic discs flanged on the inside or on the outside of the wheel

Sectored discs flanged on the inside or on the outside of the wheel

The machine is capable of refacing the brake disk; however, this should be confirmed on a case-by-case basis due to the wide variety of brake disks.

Max Chip Size: 10 mm2

2 min read

PMC-Colinet, a trusted name in pipe threading machine manufacturing, has launched an advanced 4-axis threading module designed to meet ...

5 min read

PMC-Colinet is proud to announce the completion of a major renovation at our European facility, enhancing operational capacity. This in...

2 min read

PMC-Colinet is proud to announce the successful renewal of its quality certification, reaffirming our commitment to excellence. Origina...

Ready to optimize your rail operations with precision and efficiency? Request a quote now to discover how PMC-Colinet’s high-performance wheelset reprofiling lathes can support your manufacturing process.